The first and most important thing you have to do

is accurately find Top Dead Center this is not as easy as it

first seems

the Piston has to stop before it can start gong down so

there is a dead spot at TDC where the piston is stopped but the

crankshaft is still moving

not by much but enough to put the timing out and is almost

undetectable by poking a pencil down the plug hole

So you can either take the head off and use a dial gauge to

find TDC or make a simple STOP tool from an old Spark plug

5/16 X 3inch UNF bolt fits fits nicely inside

the plug once the Porcelain insulator has been removed

Screw this into the head and turn crank gently

until it comes to a complete stop against the tool,

then back off the bolt until you can just go over TDC

screw the bolt back in by a few threads at a time so the piston

again comes to a dead stop

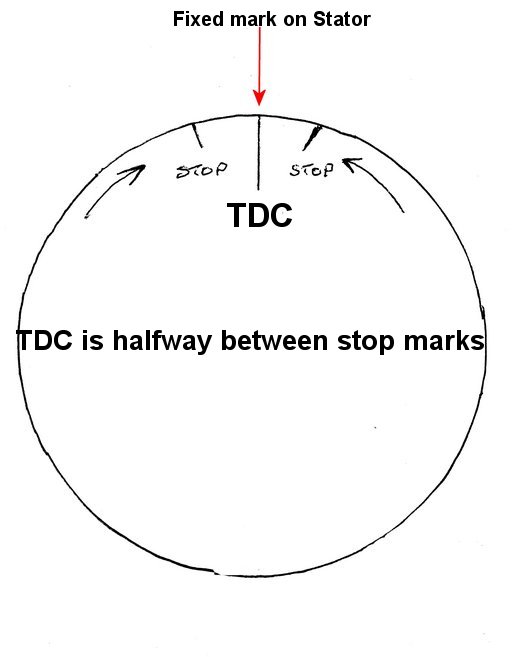

Make a mark on the rotor and another permanent mark inline with

this somewhere on the Stator that is easy to see

now turn the crank in the opposite way until you again come to a

Stop and place another mark on the rotor in line with the

permanent mark on the Stator.

Half way between the two marks on the Rotor is TDC make sure you

measure it as accurately as possible and make another mark on

the rotor

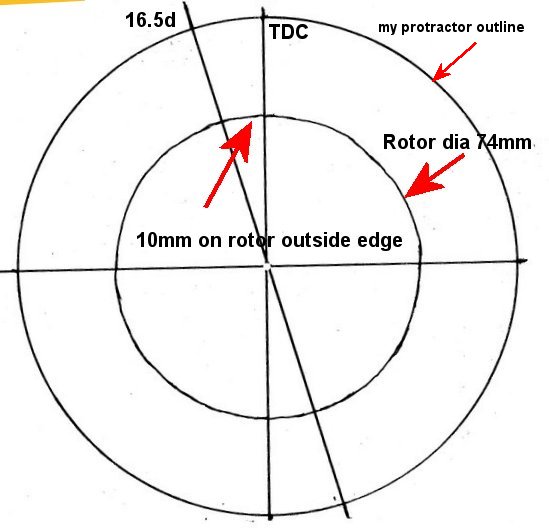

The Timing on the D14 is 16.5deg Before

TDC and the D10 19deg btdc

so now all you have to do is measure in a STRAIGHT LINE on the

VERY EDGE of the rotor 10mm backwards from TDC and make another

permanent mark, the D10 is 12mm

so when this mark lines up with the mark on the Stator points

should be just opening

easiest is to use a simple battery/ bulb across the points so

you can turn the crank back and forth and watch the bulb go out

at the timing mark.